Welcome to Leader in NDT & Inspection Service since 2007

Global Certificate: ISO 9001:2015

Welcome to Leader in NDT & Inspection Service since 2007

Global Certificate: ISO 9001:2015

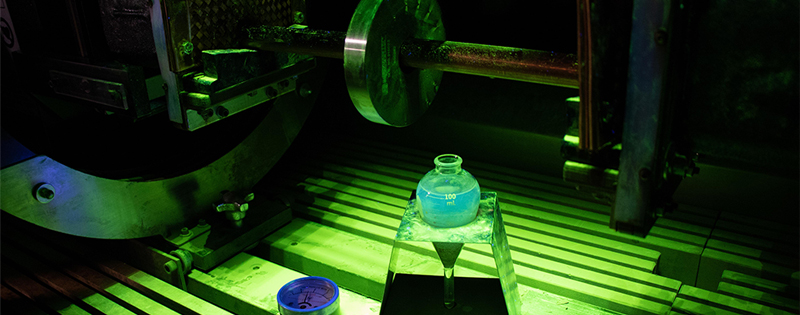

BISCO offers Magnetic particle inspection of surface & subsurface discontinuities utilizing a permanent or electromagnetic yokes for inspection of materials & welds of pipes, pressure vessels & other process equipment’s on the construction projects & process plants.

+ Can detect both surface and near-surface indications.

+ Surface preparation is not as critical compared to other NDE methods. Most surface contaminants will not hinder detection of a discontinuity.

+ A relatively fast method of examination.

+ Indications are visible directly on the surface.

+ Low-cost compared to many other NDE methods.

+ A portable NDE method, especially when used with battery-powered yoke equipment.

+ Post-cleaning generally not necessary.

+ A relatively safe technique; materials generally not combustible or hazardous.

+ Indications can show relative size and shape of the discontinuity.

+ Easy to use and requires minimal amount of training.

+ It is limited application to only on ferromagnetic materials.

+Further it is limited to disclosing only those discontinues that are at or near the surface.