Welcome to Leader in NDT & Inspection Service since 2007

Global Certificate: ISO 9001:2015

Welcome to Leader in NDT & Inspection Service since 2007

Global Certificate: ISO 9001:2015

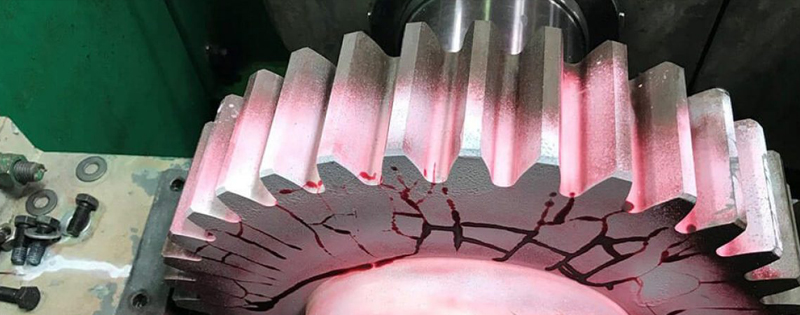

BISCO offers Liquid Penetrant testing of surface discontinuities to inspect materials & welds of pipes, pressure vessels & other process equipment’s on the construction projects & process plants.

+ High sensitivity to small surface discontinuities

+ Easy inspection of parts with complex shapes

+ Quick and inexpensive inspection of large areas and large volumes of parts/materials

+ Few material limitations (metallic and nonmetallic, magnetic and nonmagnetic, and conductive and nonconductive can all be inspected)

+ A visual representation of the flaw are indicated directly on the part surface

+ Aerosol spray cans make the process portable, convenient, and inexpensive

+ Indications can reveal relative size, shape, and depth of the flaw

+ It is easy and requires minimal amount of training

+ Only surface breaking defects can be detected.

+ Only materials with a relatively nonporous surface can be inspected.

+ Precleaning is critical since contaminants can mask defects.

+ Metal smearing from machining, grinding, and grit or vapor blasting must be removed prior to LPI.

+ The inspector must have direct access to the surface being inspected.

+ Surface finish and roughness can affect inspection sensitivity.

+ Multiple process operations must be performed and controlled.

+ Post cleaning of acceptable parts or materials is required.

+ Chemical handling and proper disposal is required.